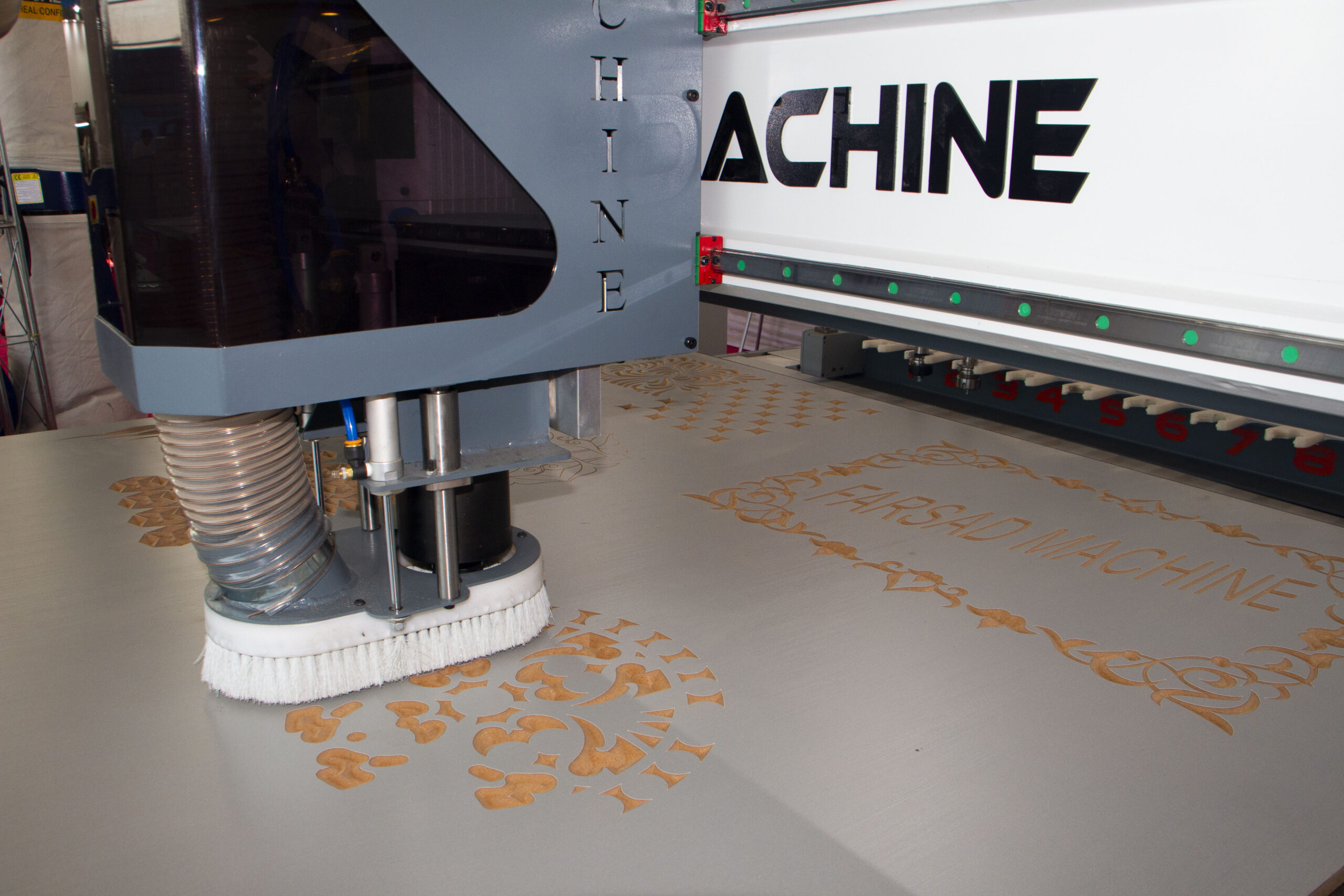

It is clear that high cutting temperature is very harmful for the cutting tools and the workpiece to be machined. Meanwhile, the cooling of the cnc machine can control the temperature as much as possible without losing the product quality and reducing the productivity of the machine. Follow this article from Farsad Machine to learn about the coolant of the wood cnc machine.

The purpose of using cnc machine coolant or cnc machine coolant

Although the word cooling is used for these materials, their role is more and beyond a normal cooling material. The design of wood CNC machines is such that the cooling material of the CNC machine is used for two roles:

CNC machine cooling

During CNC machining, a lot of heat is generated due to the friction between the tool and the workpiece, which can increase its temperature. Although ambient air can be used as a coolant, it is usually suitable for light and short-term work. But when heavy and long-term cutting operations are to be performed, the coolant of the cnc machine must be used. The presence of liquid or cooling material helps to dissipate the heat faster and complete the cutting process without friction and wear of the cutting tool.CNC machine lubrication

Instead of cooling, the coolant of the cnc machine is sent to the edges of the cutting tool and its contact with the workpiece, and is used as a type of oil to lubricate the cutting process. In fact, here the coolant of the CNC machine both removes the heat generated during machining and plays a role in removing chips and eliminating friction at the cutting site.

How to transfer the coolant to the cutting site in the CNC machine

There are several preferred methods for using CNC machine fluids, which vary according to the type of machine. In the CNC machining process, coolant is pumped with high pressure and high volume directly to the contact point of the cutting tool and the workpiece surface.This liquid moves the chips away from the workplace with great intensity, and finally, after being filtered by the splatters, it is collected and the liquid returns to the machine. With the progress of CNC machines in the last few years, the way of applying the coolant to the cutting site has changed, this liquid may be sent to the cutting site from different places.

Usually, the cooling tool or cooling system in the CNC machine is connected to the spindle so that it is possible to transfer the cooling liquid with the help of special pipes and through special tools. This cooling system delivers the cnc machine directly to the cutting tool interface. The interesting thing about cooling systems is that its pressure is very high and in some cases its operating pressure increases from hundreds to several thousand pascals